Castor Oil: A Valuable Renewable Resource to Obtain a Great Deal of Functional Materials

From kitchen shelf to one of the most sought ingredients in industries today, castor oil has come way too far and the reason is its potential to produce plenty of valuable materials for sectors of all nature from pharma, food, agriculture, adhesives, personal care, and what not.

Introduction and the Market Size

Obtained by pressing the seeds of the castor plant (Ricinus communis L.), castor oil is a non-edible, natural plant oil that consists of up to 90% of Triglyceride of Ricinoleic acid (a powerful antioxidant with anti-inflammatory properties), and 12 Hydroxy Oleic Acid. It is also high in vitamin E and omega-6 & 9 content that support the function of the cells in the body and hence is majorly used for skincare products.

Due to its renewable nature, non-competition with food, biodegradability, low costs, and eco-friendliness, the demand for castor oil has sky-rocketed in the past few years, and have found to have over 700 industrial uses already which surprisingly keeps on increasing. No wonder, the global castor oil derivatives market size is projected to reach 1.9 billion by 2030 from USD 1.21 billion in 2021.

The Fall and Fame of Castor Oil

Castor oil is an ancient treasure. Known to be the world’s oldest and most valuable herbal remedy, castor oil – the thick, golden oil is prized for its healing properties and hence was used by practitioners for thousands of years to improve the health of ancient civilizations. In fact, the oil came to be known as “the secret of beauty” in Ayurveda. But as science and technology advanced and the discovery of numerous chemicals occurred, castor oil lost its fame and began to dust away on kitchen counters until recently when its importance resurged.

The Transformation of Castor Oil

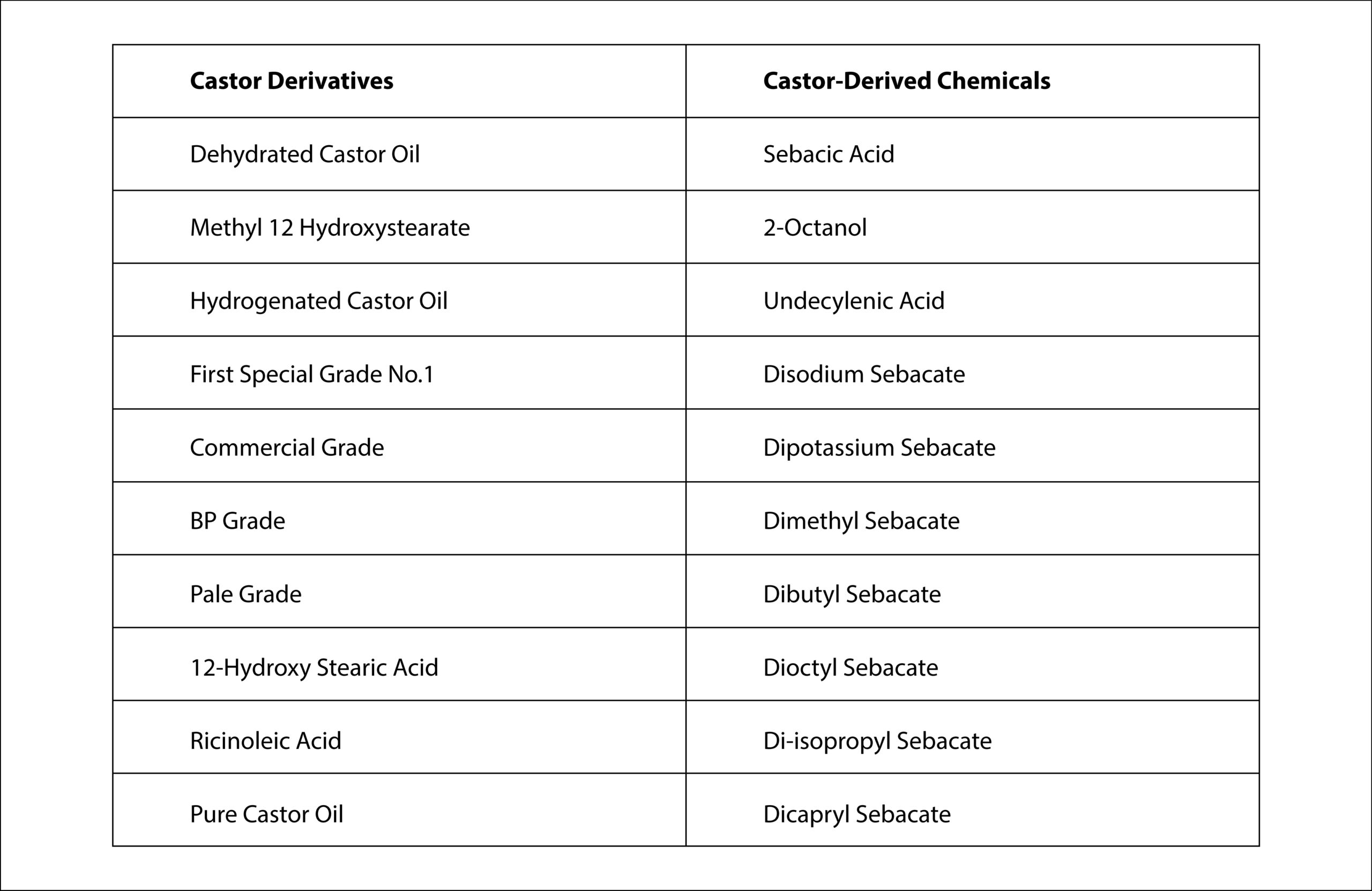

Castor oil is no ordinary oil and the multitude of functional materials it can produce is proof of it. It is such a versatile oil that with the addition of certain reactants and by carrying out various chemical reactions such as hydrogenation, carbonylation, transesterification, epoxidation, dehydration, pyrolysis, ozonolysis, sulfation, and hydrolysis, the unique properties of castor oil can be manipulated by exploiting the different functional groups such as the ester linkage, hydroxyl group, and the vinyl group and turn it into a practical renewable resource for multiple industrial uses. Here’s what all can be derived from castor oil:

Diverse Applications of Castor Oil

The nutrient-rich castor oil and its derivatives have found its place in almost all industry sectors which includes personal and beauty care, pharmaceutical, oleochemical, plastic and rubber, detergent, paints, inks and coatings, textiles, lubricants & greases, etc.

Its applications have no limit as castor oil is today the prime ingredient in the manufacturing process of various products like adhesives, brake fluids, soaps, caulks, dyes, electrical liquid dielectrics, humectants, shampoos, hydraulic fluids, body lotion, inks, lacquers, leather treatments, lubricating greases, germicidal agents, purgative, machining oils, lip gels, paints, disinfectants, pigments, skin-conditioning agents, polyurethane adhesives, refrigeration lubricants, sealants, textiles, emulsion stabilizers, washing powders, and waxes, the list has no end.

Castor oil–based Chemical Processes

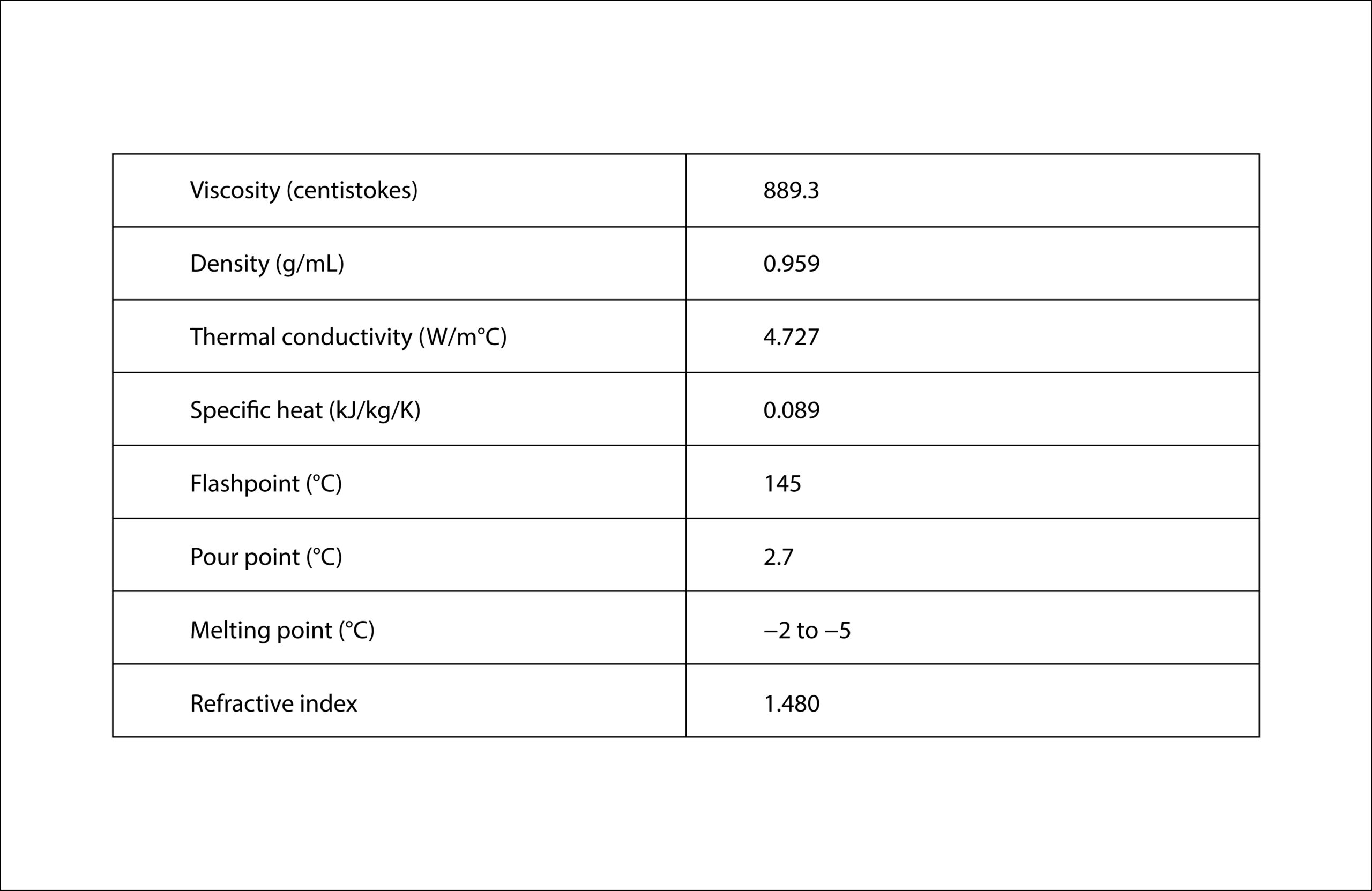

The physical properties of viscous, pale yellow nonvolatile, and non-drying castor oil makes it a suitable product for carrying out numerous chemical process. Take a look:

The presence of ester linkage, a double bond and the hydroxyl group in ricinoleic acid makes it further suitable for many chemical reactions, modifications, and transformations to name a few:

Hydrogenation – Where a hydrogen atom is introduced to the unsaturated fatty acid in the presence of a catalyst (e.g. nickel or palladium; which converts the ricinoleic acid into a saturated 12-hydroxystearic acid that is semi-solid material (wax-like) highly used in the industry for polymer materials.

Pyrolysis – An increasingly popular thermal method for converting biomass to solid, liquid, and gaseous fuels in the absence of oxygen. The pyrolysis of castor oil splits the molecule to produce undecylenic acid and heptaldehyde, preventing the combustion of biomass into carbon dioxide due to the absence of air.

Hydrolysis – Where castor oil is added slowly to 80 % caustic solution (sodium hydroxide) at approximately 250°C–360°C that produces ricinoleic acid and glycerol which upon heating at 523 K in the presence of NaOH produces capryl alcohol (2-octanol) and sebacic acid (a 10 carbon dicarboxylic acid) used extensively as a monomer for the synthesis of nylon.

Dehydration – An acid-catalyzed reaction where the major component of the castor oil – ricinoleic acid, is reacted with an acid, such as sulfuric acid or phosphoric acid, which acts as a catalyst and helps in removing the hydroxyl group in the form of water to introduce a new double bond resulting into the production of both non-conjugated linoleic acid and the conjugated linoleic acid.

Transesterification – The process of breaking down vegetable oil molecules by reacting an alcohol with an ester (in the vegetable oil) in which the glycerol functional group from the triglyceride is removed and replaced by alcohol, producing biodiesel and glycerol.

Sulphation – Turkey-red oil, widely used in textile and cosmetics industries, is obtained via sulphation of castor oil in which an SO3 group is introduced into an organic compound to produce the characteristic C-OSO3 configuration. The hydroxyl group of ricinoleic acid in castor oil is esterified by treating raw castor oil at room temperature or a temperature less than 308 K with concentrated sulphuric acid for 3–4 h.

Note: These are just a few chemical processes that we have highlighted for your knowledge whereas castor oil is treated in countless ways that lead to the production of a fleet of castor derivatives that we have today.

Final Thoughts

Exhibiting the ability to transform into alternatives to petroleum-based starting materials for the production of a wide range of industrial materials, castor oil has proved that it is in demand for a reason. With more and more discoveries happening in castor oil uses, we can see a variety of applications in the coming years, particularly as a renewable energy source.

If you are impressed with the uses of castor oil and wish to get a genuine one, note the name Ambuja Solvex – the leading castor oil manufacturer in India for it. Visit https://www.ambujasolvex.com/ to know more about us and our creations.