The fundamentals of Ricinoleic Acid

The charm of ricinoleic acid lies in the benefits it provides. Ricinoleic acid is one of the castor oil derivatives used in many products by various industries. It is an unsaturated omega-9 fatty acid and a hydroxy acid, a major component derived from the castor seeds. Castor oil is also described as ricinoleic acid triglyceride which has the availability of hydroxy functionality of fatty acid for up to 70-90%.

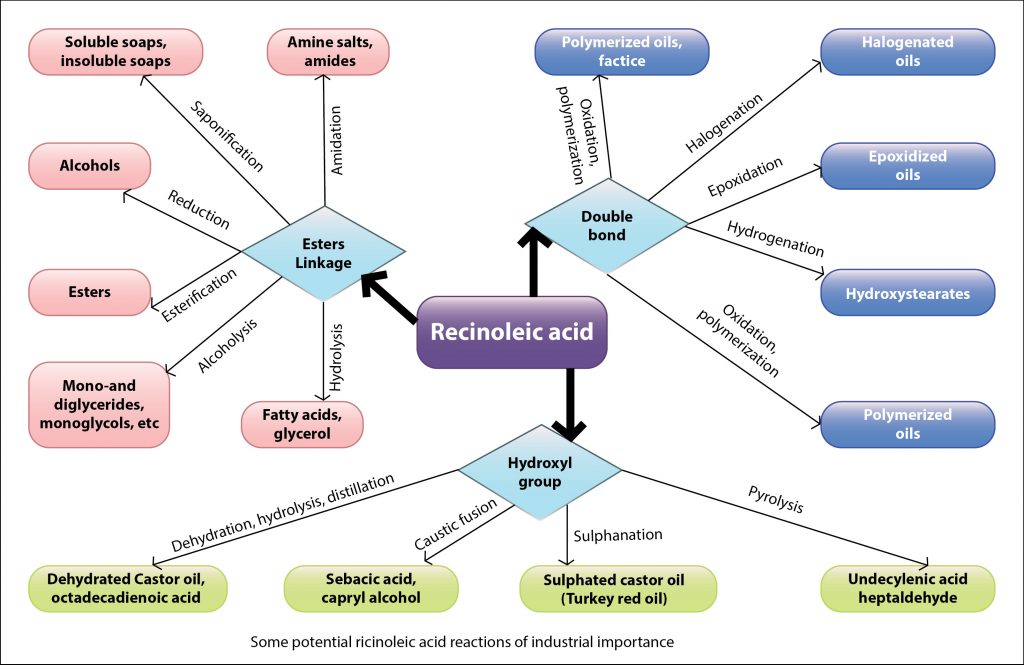

Ricinoleic acid has three functional groups which define its versatility and its importance in producing castor oil-based products. For example, carboxylic group. This group can be led to produce esterification products. The single point of unsaturation can be modified by hydrogenation, epoxidation and vulcanization. The carboxylic group transforms castor oil through reactions like esterification and amidation. The existence of a double bond transforms the castor oil through hydrogenation, carbonylation and epoxidation. The hydrogenation process transforms the liquid ricinoleic acid into a semi-solid saturated state. The semi-solid saturated ricinoleic acid is useful in resin or polymer mixtures because the oil has a high melting capacity, good storage quality, taste and odour.

The functional group hydroxyl can be acetylated, alkoxylated or removed by dehydration to increase unsaturation of the castor oil at carbon-12. Catalytic dehydration forms a new double bond in the link of ricinoleic acid which results in a conjugated acid. This type of change helps in rapid drying, excellent colour retention, flexibility and water retention for coatings.

Ricinoleic acid is derived from castor oil through the process of hydrolysis. For industrial use, mostly it is produced by saponification or fractional distillation of hydrolyzed castor oil.

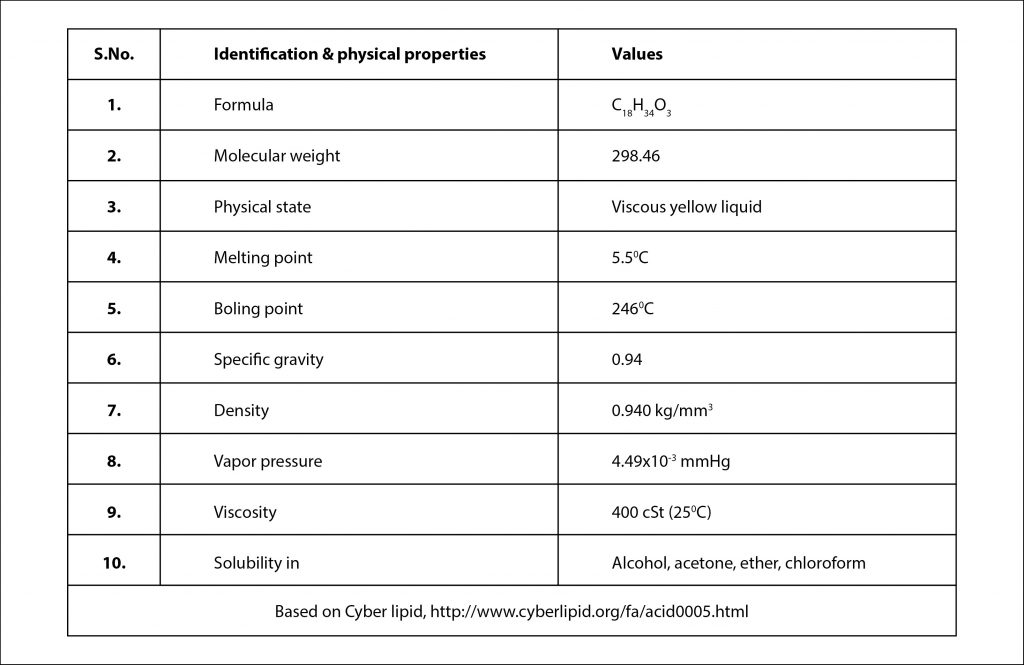

Physical properties of Ricinoleic Acid

As a hydroxy fatty acid, ricinoleic oil is used in oleochemical industries. These chemicals are similar to petrochemical commodities and can be used for various chemical applications. Castor oil is an important bio-based raw material for industrial applications. It is deemed as a suitable renewable resource for chemical reactions, modifications and transformations. Ricinoleic acid, an important castor oil derivative, is used in pigments, printing ink and textile finishing. It is also added in turkey red oil, dry-cleaning products and detergent formulations. Its different kinds of derivatives are like ricinoleyl alcohol, methyl ricinoleate, azelaic acid, and ricinenic acid are used as plasticizer and emulsifier.

Ricinoleic acid from castor oil is considered safe to use in skin products. Castor oil creates a super gloss on the skin, making products water-proof while protecting the skin. For these products, ricinoleic acid and its derivatives are used as an anticaking agent, deodorant agent, emulsion stabilizer, opacifying agent, skin conditioning agent, cleansing agent, emulsifying agent, and viscosity increasing agent of course as it has the greater viscosity than other oils which makes it superior lubricant when compared to other plant-based oils. The oxidative stability, therefore, provides longer shelf life for its products. Ricinoleic acid is soluble in polar solvents, unlike other fatty acids. The derivatives used in cosmetics are Zinc Ricinoleate, Glyceryl Ricinoleate, Ethyl Ricinoleate, Cetyl Ricinoleate, Glycol Ricinoleate, Methyl Ricinoleate, Isopropyl Ricinoleate, Potassium Ricinoleate, Sodium Ricinoleate and Octyldodecyl Ricinoleate.

The functions of ricinoleic acid provide many possibilities for it in several products depending on its usage. There are different processes to make ricinoleic acid usable for different products. Refer to the below table to know more.

Castor oil products after certain processes

Hydrogenation – Hydrogenated castor oil is best for lubricant industries because of its ability of water resistance and preservation of its lubricity. It is used in cosmetics, lubricants, paints, waxes, polishes, carbon paper, candles, crayons, etc.

Pyrolysis – This process helps in producing biodiesel and other renewable bio-based produce to use in chemical and fuel applications.

Hydrolysis – The alcohol agents produced after the hydrolysis of ricinoleic acid is used in plasticizer, dehydrator, as a solvent, anti-bubbling agent and floatation agent.

Dehydration – Derived form, linoleic acids after the dehydration of ricinoleic acid is used in the production of protective coating, varnishes, lubricants, paints, resins, primers, soaps, etc.

Transesterification – Transesterification is done to obtain biodiesel.

Sulphation – Sulfonation of castor oil produces esters like Turkey Red Oil which is widely used in textile industries and cosmetic industries by further producing detergents for lubricants, softeners, in dyeing and finishing of linen & cotton, bath oils, essential oils, shampoos etc.

Ozonolysis – 9-carbon fatty acids derived after the ozonolysis of castor oil can be used in preparing polyurethanes, polyethers and polyesters.

Polyurethane from castor oil – Polyurethane from castor oil is used in biomedical implants, coatings, cast elastomers, thermoplastic elastomers, rigid & semi-rigid foams, adhesives, sealants, flexible foams, etc.

Castor oil is the only commercially available natural oil that is produced from plant-source and that’s why it is considered safe for many applications including medical applications. The anti-inflammatory and anti-microbial properties of ricinoleic acid from castor oil can help in treating irritated skin and that’s why it is used in cosmetics and personal care products like lipsticks, skincare products, perfumes, bath soaps and also pharmaceutical products. Castor oil products are environmentally friendly because it eliminates the use of toxic chemicals that harm the environment and residents of the environment.

As a household remedy, castor oil with its benefits is used in treating skin infections, constipation, to get relief from arthritis and muscle pain and as skin and hair conditioners. It is still used for oiling grains in many households to protect against humid weather and insects. Ricinoleic acid proves to be the most important ingredient for many industries around the world.